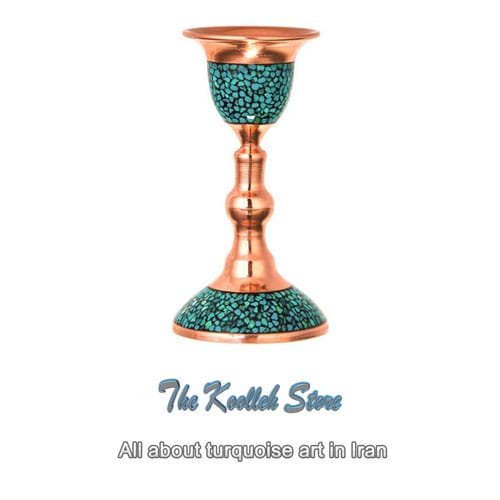

All about turquoise art in Iran

Turquoise art is one of the handicrafts that is used especially in Isfahan and in a limited way in Tehran. This art was first worked in Mashhad and as a work on jewelry such as necklaces, earrings, bracelets, etc.

Professor Ruben Yroshalami and Professor Sediqpour are among the veteran artists of Isfahan in this field. In this article, using their guidance, we introduce the art of turquoise and how to make a special work of turquoise.

The art of turquoise can be divided into 2 parts in general, which include 1) making the body and 2) placing the turquoise.

The production of a turquoise work has been discussed and the issues that should be considered in the production process of the work have been mentioned. While explaining the steps of the work, the reader of the article should try to get acquainted with the evaluation of a turquoise work and be able to identify and evaluate a distinguished and valuable turquoise work among different works by being aware of its construction stages. There are a few branches of handicrafts that have not historically had a long and long history. However, its long history has not diminished its value and prestige, and this beautiful art has been able to gain its place among other handicrafts.

This art is now performed in Isfahan, Tehran and Mashhad. Of course, in Mashhad, it is used as a user on jewelry such as necklaces, earrings and bracelets. Professor Sediqpour has learned the art of turquoise painting on jewelry from a person named Yousef Hakimian, who came to him to make jewelry, but of course he has added innovations and innovations to it. Yousef Hakimian did a limited amount of turquoise work on jewelry such as earrings, bracelets and necklaces, etc., and Master Sediqpour continued to do so for a long time to come.

Body construction

At this stage, the desired object is made with the metal selected by the master craftsman in the bending workshop. Metals that can be used for turquoise include copper, brass, bronze and silver, which are preferred over copper and brass. The container (infrastructure) desired by Master Firoozeh Koob is produced by the master of bending work with copper or brass by special tools of this technique.

It is noteworthy that during the bending process, the thickness of the container is the same in all parts, especially in the angled parts. Otherwise, the damaged metal may rupture during turquoise and final polishing.

The thickness of the metal used in turquoise depends on the size of the container and varies from 0.3 cm to 1.5 cm. And depending on the size of the container, the thickness of the container will change. For smaller containers, a thinner copper sheet is used, and for larger containers, a thicker copper sheet is used.

Bending in Isfahan takes place in Hassanabad area and bending workshops are centrally located in them.

In addition to the steps that can be taken to make other dishes, there is a step called “Nekar Kari” for making a body for turquoise. At this stage, the parts of the container that are going to be turquoise will be lowered by an angle of 90 degrees, about 2 to 3 mm.

According to Professor Yroshalami, the operation involved the construction of a turquoise body from personal innovations called Bahrami. Prior to that, “strings” were used instead of “nekkari”. In this way, strands of their own kind, 2 to 3 mm thick, were soldered to silver on the top and bottom of the part where the turquoise was to be made.

“Unemployment” further strengthens the container in the face of possible shocks. There were problems with the digging process, including the fact that the solder could melt during heating and cause the filament to separate, creating problems for the turquoise master. On the other hand, the string, which was soldered to the smooth surface of the dish and accommodated the turquoises, gave a special charm and effect to the effect due to the prominence it creates in the dish. Nowadays, digging is still used in turquoise parts of the container to create space and create creativity. After the infrastructure has been prepared in the bending workshop, it is time to work in the turquoise workshop.

The turquoise used in the turquoise workshop is made from turquoise masonry workshops in Mashhad or Firooz mines in Neishabour. Turquoise is priced by bitumen in terms of color, size and no lumber. The rocks contain some impurities and soil that must first be washed away.

In the workshop of Professor Yoroshalami, this work is done in a device called Gholstan. In this way, the turquoises are poured into this machine with a little water, and after a few hours, during the rotation of the machine and the collision of the stones, the soil and its impurities are taken together. After washing and drying, it is time to grind the turquoise stones. At this stage, turquoise stones are classified according to their shape and size from 1 mm to 4 mm in the form of tablets and pollen. The stones are used according to the size of the container and the surface on which the turquoise is placed. For example, for flat works such as mirrors, turquoise stones of a plate that are lower in height and wider are used.

Put the varnish on the dish

At this stage, first the lacquer, which is like a layer of tree bark, is pounded and the resulting brown-gold powder is mixed with califen. (High quality turquoise lacquer is a lacquer obtained from walnut wood distillation.) (Calfine is obtained from turpentine. 4)

Changes in the ratio of lacquer and cauliflower can cause problems, such as: Excessive use of cauliflower can cause small bubbles in the work. These bubbles are caused by the dissolution of California in polyester. In this way, the grains of cauliflower are not melted during the correct work and then in the polyester stage, these grains are dissolved in the polyester and cause bubbles on the surface of the work. Yellow spots that may be seen in parts of the lacquer are also due to the presence of impurities in the cauliflower and the lacquer or the melting of the cauliflower. It is noteworthy that in smaller bodies can be used relatively more cauliflower, but in large bodies more use of cauliflower reduces the strength of the varnish and finally turquoise. At this stage, first the desired container a little They heat up. The prepared powder is then poured into the lacquer and cauliflower, heated by the burner to melt, and repeated several times until the thickness of the layer created reaches the height of the perforated part for turquoise. Care should be taken when heating the varnish, as excessive heat will cause the varnish to burn, in which case the varnish will lose its adhesiveness.

Put turquoise on the body

At this stage, the turquoise stones that are washed and nested are selected according to the size of the container. Larger stones are usually used for large containers and smaller stones for small containers.

The most appropriate way to place turquoise stones is to place them in the double-glazed part. This means that it is better to first arrange the stones at the top and bottom of the turquoise part (in the bin of the container) and then the other parts.

First, heat the lacquer a little to soften it, then place the turquoise stones that have been heated on the lacquer. This is done by pliers and by pressing the pliers, the stones are inserted into the lacquer. To speed up the work, some turquoise stones are poured on the lacquer and then the place and location are adjusted with pliers.

Sitting turquoise requires the patience and precision of a turquoise artist, because the less stones are placed together and the less blurred the varnish is, the more beautiful and eye-catching the work will be. It should be noted that the stones should be placed on the lacquer from the widest side so that the gaps created between the stones are minimized after eating. Here, too, precision in heating the varnish is important. As mentioned, too much heat will cause the varnish to burn. Easy to move and carry the infrastructure It has been polished again. Pour the prepared powder of lacquer and califen in the desired part and heat it a little so that the lacquer melts and fills the desired place. Stone concrete is also used in some parts of the work. Stone concrete includes: Mel powder, flaxseed oil and paint powder. Where turquoise concrete is needed, the last powder, black and brown, is used.

Turquoise turquoise stones

Turquoise is polished by the sapphire plate. The sanding pad or sandpaper used for this purpose: For harder stones, the plate number 40 is rougher and has a larger grain size, and then in the next step, the sand plate No. 80, which has a smaller grain size and is of the type Carbide is aluminum.

Experience has shown that turquoise stones that are darker and more bluish in color are harder than lighter turquoise stones. When grinding turquoises, be sure to place a stream of water on the subfloor to prevent the crumbs from splashing while preventing the subfloor and turquoise from heating up.

Turbidity of turquoise stones should be such that their surface is in line with the surface of the container and is perfectly smooth and uniform. This stage also requires the accuracy and skill of the turquoise artist, because over-rubbing the turquoises causes the part of the work to become hollow and indented, and ultimately causes a defect in the work.

After the sanding work has been completed by the sub-plate and the turquoises have become smooth and even, some parts of the work may have a stone separated from the varnish or no part of the varnish at this stage. They do it with a stone putty. The use of stone concrete allows the master to grind and smooth that part. The turquoise surface is then polished with a soft sandpaper to make it completely polished.

This is done by sanding No. 60 to achieve the softest ice sanding No. 1400. Of course, this operation may be performed after the wheel of the metal surface of the container. At this stage, all the turquoise-stamped works are sent to the wheel workshop. To make the metal surface of the body of the container smooth and polished by the wheel machine, because scratching and dirt on the metal surface is inevitable while working.

The final step in making a turquoise effect is to beat the polyester into a container. The polyester acts as a protective coating and prevents scratches on the metal body of the container. Of course, this depends on the taste of Firuh Koob and of course the customers of the work. If many of Master Sediqpour’s works have not been eaten by polyester, in his opinion, polyester reduces the originality of the work and without it, the audience establishes a better and more intimate relationship with the work.

Turquoise-painting is like other branches of artistic handicrafts that can be added to its beauty and eye-catching with creativity, initiative and innovation. Among the initiatives that turquoise artists have used in creating their works, we can see the following examples Cited :

– Work on a part of the body of the container and create space by stringing. It seems that using this method, works with different and varied applications can be produced and marketed

– Combining the art of turquoise and metal mesh. Simultaneous use of these two arts (turquoise-cutting-netting) helps to create a visual balance in a work. Because the lightness and the existence of empty spaces in the Berry network are in contradiction with the weight of turquoise, and this contradiction leads to the creation of balance. Of course, the use of a grid along with turquoise requires special care, because the body of a turquoise effect should not be too light, in which case the probability of damage to the effect is much higher.